We know that most of the construction sites are very busy now. Every day, tens of thousands of tons of…

Concrete bathing plant models include HZ, 2HZ, HL, 2HL series, each followed by numbers representing capacities which are further divided by scales. Concrete mixers have their own represent letters, too. Types of plants can also be divided by application scopes.

Design details in building a concrete batching plant entail building area, layout of plant units, route for vehicles, distance from raw material and construction sites etc.

The control system of concrete batching plants has a life cycle. Generally, most of the electrical components will age after 4 to 5 years of use. The price of the control system before the modification is much cheaper than the brand new control system after the transformation. Some people would choose to remould part of the system, while others believe it’s better to replace all the parts of the old system.

Learn more about the configuration, capacity, price, advantages, disadvantages and application scope of dry mix concrete batching plants here.

The construction of a stationary concrete batching plant generally includes site planning, running procedures, ordering equipment, foundation construction and equipment installation. Among them, the foundation construction should be planned at the same time as the equipment is ordered.

The procedures for qualification of concrete batching and mixing plant are as follows: 1. The ready mixed commercial concrete mixing…

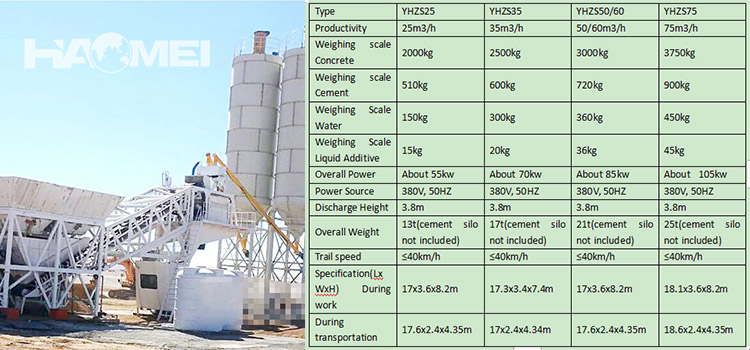

HM Machinery is among leading mobile mobile concrete batching plant manufacturers in China. We supply 25m3, 35m3, 50m3, 60m3 and…

A mobile batching plant with concrete pump usually does not consist of a complete set of mobile plant and a…

Mobile concrete batching plant manufacturers supply mobile plants of 25m3 to 75m3 per hour. A mobile plant is compact in…