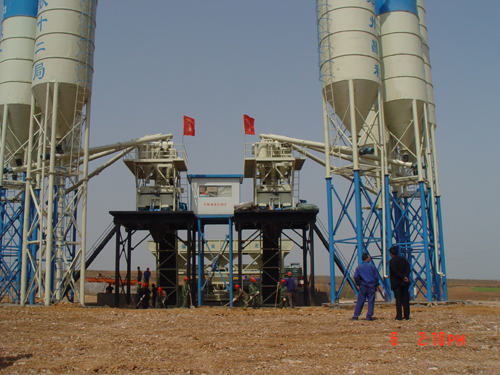

The mixing system is core configuration of concrete batch plant

The Mixing System use twin shaft forced type concrete mixer which has high mixing evenness for concrete, short mixing time, long lifespan for wearing parts, easy operation and maintenance advantages. 4.2 m discharging height. Adjustable hydraulic discharging door angle. High Wear-Resistant Chromium-Manganese Alloys Plates and Blades. Auto lubrications. The main shaft driving system refers to Italian SICOMA technology. Perfect shaft end sealing system effectively prevents leakage and guarantees the continuous long running of whole mixing system.

So the maintenance of mixing system is important,batching plant manufacturer Invite you to look at the maintenance work of the mixing system.

1.Check if the shaft end seal cavity, distributor import and export, and seal tube line is block or be full of grease, is there enough lubricating oil (grease) at all lubricating points and deceleration box every time before working.

2. Every time before working, to observe if the oil in oil storage barrel of electric lubrication pump is used up, to fill in time when the oil close to use up, running without oil are not allowed.

3. The accumulated material in the inside and outside of mixing tank and in the discharge door must be clean up and be rinsed with water. The adhesive materials which can be rinsed should be been chiseled off at a regular every time after working.

4. The mixing blade must be adjusted and tightened once a week, in order to avoid the leaf come off and cause accidents.