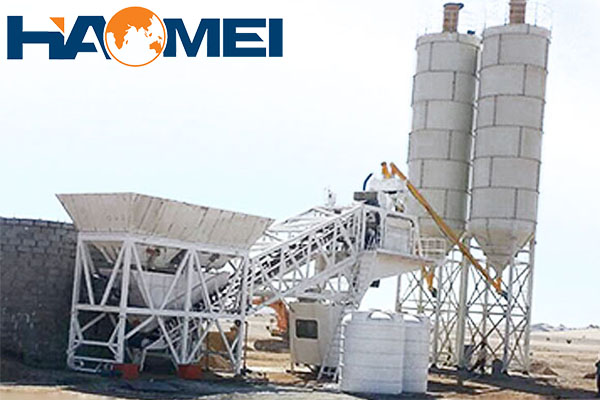

Mobile concrete batching plant manufacturers supply mobile plants of 25m3 to 75m3 per hour. A mobile plant is compact in structure, small in floor area, easy to install and high in automation, widely used in road and bridge, construction, water conservancy, electric power and other infrastructure construction.

Components from mobile concrete batching plant manufacturers

- Chassis of the main engine: the chassis of the mixing main engine is in the form of cantilever, which includes the traction pin of the towing truck and the parking leg; the measurement scale of the mixer, cement and water admixture is placed on the chassis; the surrounding is equipped with the inspection walking platform, handrail, etc.

- Control room: the control room is located at the bottom of the chassis of the concrete mixer machine, which is equipped with the full-automatic control system of the mixing station. The control system is the same as that of the fixed mixing station. The control room is used as the front support point of the whole station in the working state, and the control room is folded up and stored in the air in the bracket during the transfer transportation; all its control lines do not need to be disassembled.

- Aggregate batching and metering: this system is located at the back end of a mobile plant, and the upper part is the aggregate (sand, stone) storage hopper composed of 2 or 4 grids. A heightening plate is set to increase the storage capacity, and the pneumatic door is opened in turn. Aggregate metering is a multiple material cumulative metering method. The bottom is equipped with a walking rear bridge and a frame leg for working.

- Belt conveyor frame: the frame is a truss structure connecting the chassis of the main machine and the aggregate batching frame, with a belt frame inside; the main frame, belt frame and batching frame are integrated to form the main structure of the whole mobile concrete batching plant.

- Peripheral parts: mainly incorporate cement bins and screw conveyors. These are an integrated unit either in working or travel state of the plant, making both site transfer and installation simpler.

- Mixing machine: JS type forced concrete mixer is adopted to mix the fluidity and dry hard concrete quickly and evenly.

Configuration from mobile concrete batching plant manufacturers

| Type | YHZS25 | YHZS35 | YHZS50/60 | YHZS75 |

| Productivity | 25m3/h | 35m3/h | 50/60m3/h | 75m3/h |

| Weighing scale Concrete | 2000kg | 2500kg | 3000kg | 3750kg |

| Weighing scale Cement | 510kg | 600kg | 720kg | 900kg |

| Weighing Scale Water | 150kg | 300kg | 360kg | 450kg |

| Weighing Scale Liquid Additive | 15kg | 20kg | 36kg | 45kg |

| Overall Power | About 55kw | About 70kw | About 85kw | About 105kw |

| Power Source | 380V, 50HZ | 380V, 50HZ | 380V, 50HZ | 380V, 50HZ |

| Discharge Height | 3.8m | 3.8m | 3.8m | 3.8m |

| Overall Weight | 13t(cement silo not included) | 17t(cement silo not included) | 21t(cement silo not included) | 25t(cement silo not included) |

| Trail speed | ≤40km/h | ≤40km/h | ≤40km/h | ≤40km/h |

| Specification(LxWxH) During work | 17×3.6×8.2m | 17.3×3.4×7.4m | 17×3.6×8.2m | 18.1×3.6×8.2m |

| During transportation | 17.6×2.4×4.35m | 17×2.4×4.34m | 17.6×2.4×4.35m | 18.6×2.4×4.35m |

Price from from mobile concrete batching plant manufacturers

If you need to learn about prices of moible cement plants, please contact us at [email protected], and we will give a price list based on the model and configuration you need.