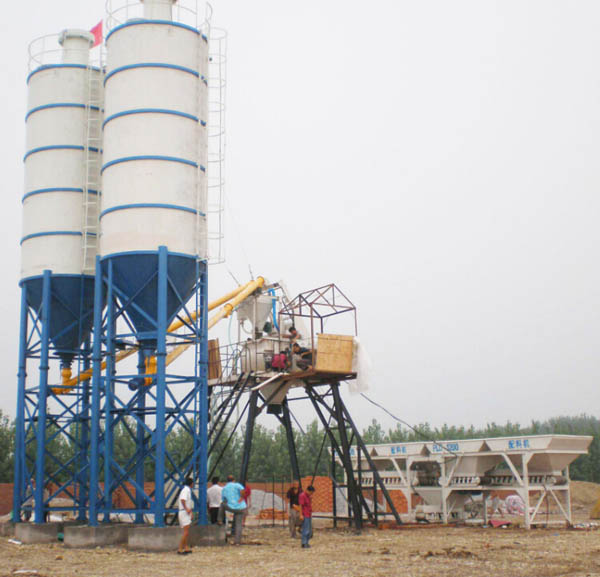

HZS35 engineering concrete batch plant configuration flexible, small footprint, more suitable for installation in the construction site, take a look at it’s production process.

HZS35 concrete batch plant mixing console and aggregate ascend with double shaft JS750 forced concrete mixer, aggregate ingredients part adopts PLD1200 type concrete batching machine, loader feeding, electronic scale metering, its working process is as follows:

1. Cement storage by the cement warehouse, conveyor screw conveyor, cement scale measurement;

2. Water from the tank and reservoir storage, pump water supply, water scale measurement;

3. Liquid admixture in the additive storage tank Stir the corrosion pump into the admixture scale for measurement.

4. Cement, fly ash through the screw conveyor into the measuring hopper, when the delivery volume and set the same value, the computer sends a signal to stop the delivery, control the bottom of the cement weighing bucket pneumatic butterfly valve so that the material inside the cement bucket cement mixer.

5. The ingredients and the mixing process is controlled by the electronic control system automatically (also can be manual control), in all material discharged into the JS750 dual-axial blender concrete mixer, began to stir.To the stirring time, open the unloading door discharge, a mixing process is completed.